Understanding the Ditch Witch Parts Manual

The Ditch Witch parts manual is more than a simple list; it’s vital. It ensures your equipment runs smoothly. The manual contains crucial information for identifying and ordering the correct parts‚ minimizing downtime‚ and optimizing performance‚ as stated on 02/05/2025.

Importance of the Parts Manual

The Ditch Witch parts manual is an indispensable tool for anyone involved in the maintenance and repair of Ditch Witch equipment. Think of it as the definitive guide to keeping your machinery operational. Without it‚ identifying the correct replacement parts becomes a time-consuming and potentially costly guessing game.

The manual’s primary importance lies in its ability to provide precise part numbers and detailed diagrams. This ensures you order the exact component needed‚ preventing compatibility issues and minimizing downtime. Access to the correct parts leads to efficient repairs‚ keeping your projects on schedule and within budget.

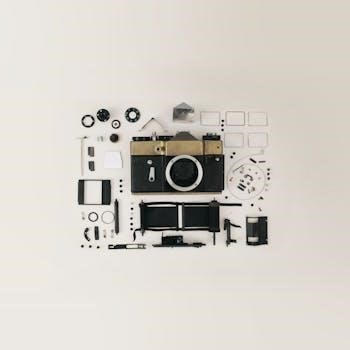

Moreover‚ the parts manual often includes exploded views of assemblies‚ offering a clear understanding of how components fit together. This is invaluable for troubleshooting problems and performing accurate repairs. It allows technicians to visualize the machine’s construction‚ leading to faster and more effective solutions‚ as well as preventing more damage.

Accessing the Correct Manual

Gaining access to the right Ditch Witch parts manual is crucial for effective maintenance and repair. The first step involves accurately identifying your Ditch Witch model number and serial number. This information is typically found on a plate or sticker affixed to the machine’s frame.

Once you have this information‚ you can explore several avenues for obtaining the correct manual. Ditch Witch offers a “Parts Lookup” tool on their website‚ allowing you to search for manuals using your model and serial number. This online tool provides access to digital versions of manuals‚ which can be easily downloaded and printed.

Alternatively‚ you can contact your local Ditch Witch dealer. Dealers possess a comprehensive library of manuals and can assist you in locating the specific one for your equipment. They may also offer printed copies of the manual for purchase. Ensuring you have the correct manual will streamline the parts identification and ordering process.

Navigating the Ditch Witch Parts Manual

Accurately identifying your Ditch Witch model is the first step. Locate the model and serial number‚ often on a plate on the machine’s frame. This information is essential for finding the correct parts within the manual.

Identifying Your Ditch Witch Model

Before diving into the Ditch Witch parts manual‚ the most crucial step is correctly identifying your machine model. Ditch Witch offers a diverse range of equipment‚ from trenchers and directional drills to vacuum excavators and skid steers‚ each requiring specific parts.

Locating the model and serial number is paramount. Typically‚ this information is found on a metal identification plate affixed to the machine’s frame. The plate may be located near the operator’s station or on the main body of the equipment. Take a moment to carefully examine your machine and note these details.

The model number provides a general overview of the machine’s type and capabilities‚ while the serial number offers a unique identifier for your specific unit. This serial number allows you to access the precise parts list relevant to your machine’s configuration. Using the wrong parts manual can lead to ordering incorrect components‚ resulting in wasted time‚ money‚ and potential damage to your equipment.

Double-checking the model and serial number against the information in the parts manual is always recommended to ensure accuracy. Some Ditch Witch models may have variations or modifications that affect the parts required. Taking this extra step can save you from costly errors and keep your equipment running smoothly.

Understanding Part Numbers and Diagrams

Navigating a Ditch Witch parts manual effectively hinges on understanding part numbers and diagrams. Each component within the manual is assigned a unique part number‚ serving as its primary identifier. These numbers are crucial for accurate ordering and communication with parts suppliers.

The diagrams are just as important. They are exploded views‚ showcasing how parts fit together. These visual representations offer a clear understanding of the assembly‚ disassembly‚ and location of each component within the machine. They often accompany detailed lists of part numbers‚ making it easier to locate the exact item you need.

Pay close attention to any notes or symbols accompanying the diagrams. These indicators might specify quantities‚ material types‚ or critical installation instructions. Ignoring these details could lead to incorrect assembly or the use of the wrong replacement part.

When searching for a specific part‚ cross-reference the part number with the diagram. Verify the shape and location of the component in the diagram match what you are looking for on your machine. This visual confirmation minimizes the risk of ordering the wrong part.

Remember‚ Ditch Witch parts manuals often include multiple diagrams for different sections of the machine. Ensure you are referencing the correct section for the part you need. Being thorough and detail-oriented will save you time and money.

Key Components Covered in the Manual

Ditch Witch parts manuals comprehensively cover key components. This includes engine parts‚ hydraulic systems‚ and transmission components. Detailed diagrams and part numbers facilitate easy identification and ordering. This ensures proper maintenance of your equipment.

Engine Parts

The engine section of a Ditch Witch parts manual is critical. It offers detailed breakdowns of all engine components. This includes everything from filters and gaskets to more complex parts. Examples are cylinder heads and fuel injectors. According to deutzsupport.com‚ whether your Ditch Witch uses a DEUTZ engine or another‚ the manual is invaluable for identifying the correct parts for service and repair.

You’ll find part numbers‚ diagrams‚ and exploded views to aid in locating and understanding each component’s role within the engine. Regular maintenance with genuine Ditch Witch parts ensures optimal engine performance and longevity. This section typically covers parts for various engine models used across the Ditch Witch product line. This allows users to easily find parts specific to their machine. Furthermore‚ it aids in preventing downtime‚ ensuring the equipment remains operational and efficient.

The manual helps in proper engine maintenance. It ensures that the engine runs smoothly and efficiently.

Hydraulic System Parts

The hydraulic system section within the Ditch Witch parts manual is essential for maintaining the equipment’s functionality. This section details all hydraulic components. It includes pumps‚ motors‚ valves‚ cylinders‚ and hoses. Each component is crucial for the machine’s operation. The manual provides exploded views and part numbers. These visual aids are invaluable for identifying and ordering the correct replacement parts.

Proper maintenance of the hydraulic system is vital for the performance and longevity of Ditch Witch equipment. Using the correct hydraulic fluids and filters‚ as specified in the manual‚ is critical. Regular inspections and timely replacements of worn or damaged parts prevent costly breakdowns. The manual aids in identifying potential issues. It helps in maintaining optimal hydraulic system performance. It ensures smooth and efficient operation of the machine. Moreover‚ it helps extend the lifespan of the hydraulic components.

This is vital for minimizing downtime and maximizing productivity on the job site. It is important to use this section effectively.

Transmission and Drivetrain Parts

The transmission and drivetrain section of the Ditch Witch parts manual is critical for maintaining mobility. This section covers essential components like gears‚ shafts‚ bearings‚ and clutches. It also includes the drive axles and other parts. These parts are essential for transferring power. They ensure the machine moves efficiently. The manual provides detailed diagrams. It also has part numbers for easy identification.

Regular maintenance of the transmission and drivetrain is crucial. Proper lubrication and timely replacement of worn parts‚ as detailed in the manual‚ are essential. These measures can prevent costly repairs. Consulting the manual ensures the use of the correct parts. It also guarantees proper installation. This ensures the machine operates smoothly and efficiently. Understanding this section minimizes downtime. It also maximizes the lifespan of the drivetrain components.

This section provides a comprehensive overview of the parts needed. It ensures the Ditch Witch equipment remains mobile and productive. It is important for optimal performance.

Finding Parts and Ordering Information

The Ditch Witch parts lookup tool is your gateway to finding the exact components you need. It allows searching by part name‚ model number‚ or serial number‚ simplifying the process. This quickly provides accurate part identification and ordering details.

Using the Parts Lookup Tool

The Ditch Witch Parts Lookup tool is a critical resource for efficiently sourcing replacement parts. This online tool simplifies identifying and ordering the correct components for your specific Ditch Witch equipment. It eliminates guesswork and ensures you get the right part the first time‚ minimizing downtime and saving valuable time and resources.

The tool allows you to search by part name‚ model number‚ serial number‚ or keywords‚ providing multiple avenues to locate the desired item. By entering your equipment’s serial number‚ you can access a detailed parts list specific to your machine’s configuration‚ ensuring compatibility and proper fit. The tool also provides exploded diagrams and detailed illustrations‚ further aiding in accurate part identification.

Once you have identified the required part‚ the Parts Lookup tool facilitates the ordering process. You can typically request a quote from your local Ditch Witch dealer directly through the tool. This seamless integration streamlines the procurement process‚ enabling you to quickly obtain pricing and availability information. The tool streamlines parts acquisition‚ keeping your equipment operational.

Contacting Local Dealers for Parts

When it comes to sourcing Ditch Witch parts‚ your local Ditch Witch dealer is an invaluable resource. Dealers possess in-depth knowledge of Ditch Witch equipment and parts‚ enabling them to provide expert assistance in identifying the correct components for your specific needs. They offer personalized support‚ ensuring you receive the right parts to keep your machinery running smoothly.

Local dealers can help if you are unable to find a specific part in the manual or need clarification on part compatibility. They can leverage their expertise and access to Ditch Witch’s resources to locate even hard-to-find parts. Furthermore‚ dealers often provide valuable advice on maintenance and repair procedures‚ helping you troubleshoot issues and extend the life of your equipment.

Establishing a relationship with your local dealer fosters trust and ensures you have a reliable partner for all your parts needs. They can offer competitive pricing‚ timely delivery‚ and ongoing support‚ contributing to the overall efficiency and profitability of your operations. Contacting your local Ditch Witch dealer is a proactive step towards minimizing downtime and maximizing the performance of your equipment.

Troubleshooting with the Manual

The Ditch Witch parts manual is an invaluable tool for troubleshooting. It assists in identifying problems efficiently. Diagrams aid in understanding the assembly‚ enabling precise repairs‚ ensuring minimal downtime‚ and optimized machine performance‚ as stated on 02/05/2025.

Identifying Common Problems

Using the Ditch Witch parts manual for troubleshooting begins with identifying common issues. This could range from engine malfunctions‚ often indicated by unusual noises or reduced power‚ to hydraulic system failures‚ noticeable through leaks or sluggish operation. Transmission problems might manifest as difficulty shifting or unusual grinding sounds.

Electrical issues can also arise‚ affecting starting or lighting systems. Consult the manual’s troubleshooting section to diagnose these symptoms. The manual also contains information about the parts used in Ditch Witch JT2020‚ JT3020 All Terrain and Ditch Witch JT3020 Mach 1. Look for common failure points identified in diagrams and descriptions.

Regular maintenance is vital in preventing these problems. Filter checks‚ fluid level inspections‚ and component wear assessments‚ detailed in the manual‚ can proactively detect potential issues. By cross-referencing symptoms with the manual’s diagnostic charts‚ users can pinpoint faulty parts and plan repairs efficiently‚ ensuring minimal downtime and optimized equipment performance.

Addressing these problems in time can save time and money. Look for signs of wear and tear‚ and use the manual to find the correct parts.

Using Diagrams for Repair Assistance

The diagrams within the Ditch Witch parts manual serve as invaluable visual aids during repair processes. These detailed illustrations provide exploded views of various components‚ offering a clear understanding of how parts fit together. When tackling a repair‚ begin by carefully examining the relevant diagram in the manual. Identify each part‚ noting its position and relationship to surrounding components.

These diagrams help in disassembling complex assemblies‚ ensuring no parts are missed or damaged. The manual shows how to fix hydraulic‚ transmission‚ electrical and engine components. Use the diagrams to locate parts and how they’re connected. When reassembling‚ refer back to the diagrams to guarantee proper alignment and connection of all components.

Pay close attention to torque specifications and any special instructions noted in the manual alongside the diagrams. Moreover‚ the diagrams often highlight potential wear points or areas prone to failure. By studying these‚ technicians can proactively address potential issues‚ replacing worn parts before they cause further damage.

The manual is a great tool when used with diagrams.